100% Pure TALALAY Classic, Natural and Organic Latex Foam Pillows

-

Latex Pillows

-

Latex TALALAY Pillow

-

100% Natural Pillows

-

Organic Pillows

Latex Pillows

Latex TALALAY Pillow

100% Natural Pillows

Organic Pillows

Sleep is the most natural thing in the world. And you can sleep more soundly, more deeply on pillows made ofTALALAY foam. Derived from the natural milk of the rubber tree,TALALAY foam pillows conform to the delicate neck and head areas for superior support and comfort.

The leading supplier of TALALAY pillows in the

world

The leading supplier of TALALAY pillows in the

world

Latex International (LI) leads the industry with our TalatechAcirc; brand of TALALAY foamacirc;#128;#148;the world quality standard. Itacirc;#128;#153;s the only TALALAY made in the U.S.A. and the finest in the world. TALALAY naturally conforms to the contours of the head and neck for superior comfort and support. Our superior products and services have helped build the most successful latex retail pillow programs.

With a wide range of TalatechAcirc; latex pillow products supported by extensive market research, innovative packaging and creative merchandising,TALALAY Globalhelps develop complete covered pillow programs to fit your marketing needs.

LI's pillow product portfolio features a wide range of products including Classic TALALAY, Specialty Pillow Designs, and our own brand of RejuveNiteacirc;#132;#162;.

TALALAY PILLOW BRANDS

TALALAY PILLOW BRANDS

Rejuvenite

Our Classic TALALAY latex is one of the only pillow technologies that can naturally create different firmness levels. Theyacirc;#128;#153;re available in three comfort ranges: Plush acirc;#128;#147; ideal for stomach sleepers or "pillow scrunchers", Medium acirc;#128;#147; perfect for back sleepers, and Firm acirc;#128;#147; a great fit for side sleepers.

High Profile acirc;#128;#147; Ideal for side and back sleepers. 100% natural latex pillows are produced using natural latex sustainably extracted from rubber trees for TALALAY production.

Low Profile - Ideal for stomach and back sleepers. Uses natural, biodegradable ingredients that come from renewable resources.

NOW! for the World's Most Comfortable Latex Pillows from LATEX PEDIC. Sleep easier in unbelievable comfort. The time your neck can get the right balance of comfort and support has a lot to do with the way you feel. If you are waking up with neck pain, your pillow may not be offering you the right balance of comfort and support. The 100% Pure TALALAY Latex Pillows from LATEX PEDIC are available in Classic Twin/Standard Queen and King in (3) different firmnesses: Plush, Medium and Firm; The 100% Natural Latex Pillows are available in Queen and King in (2) two different firmnesses: Low Profile (medium) and High Profile (firm). Select a Latex Pillow for your personal use, and take a health break.

Latex Pillows

Latex TALALAY Pillow

100% Natural Pillows

Organic Pillows

Los Angeles Latex Pillows Los Angeles CA

PLEASE CALL 800-551-2010 FOR LA-LOS ANGELES'S BEST PRICES, QUALITY, GUARANTEE AND SERVICE FOR

NATURAL LATEX FAOM PILLOWS

ORGANIC LATEX FAOM PILLOWS

100% PURE TALALAY LATEX FAOM PILLOWS

SOFT LATEX PILLOWS

FIRM LATEX PILLOWS

100% Pure TALALAY Classic, Natural and Organic |

|

|

|

7"

Latex

Mattress 8.5" Perfect Firmness 9" High Profile 11" THE ULTIMATE |

Electropedic Models:

WH1,

WH2,

WH3 Sizes: Twin, Full, Queen, King, Duals Queens amp; Dual Kings Adjustable Bed Mattresses: Spring, Air, Memory amp; Latex Adjustable Bed Manufacturers |

Adjustable

Bed,

Bariatric

Bed,

Hospital

Bed Stair Lift, Lift Chair amp; Massage Chairs Mobility Scooters amp; Electric Wheelchairs Scooter Lift, Wheelchair Porch Elevators |

100% Pure TALALAY Classic, Natural and Organic Latex Foam Pillows. Call 800-528-3974

What actually is it?

Natural Latex is a milky substance harvested from rubber tree plants (Havea brasiliensis) which are grown in tropical climate plantations around the world. Most are located in Africa, Malaysia, South America, and Indonesia. Natural Latex is bio-degradable and naturally resistant to mold, mildew amp; bacteria.

Harvesting the liquid latex is similar to tapping trees for maple syrup. The trees are not harmed, providing a sustainable resource. The latex is collected in buckets and shipped to large rubber factories such as B.F Goodrich, Dupont, etc. for processing. Natural liquid latex is a commodity thatacirc;#128;#153;s publicly traded in stock markets around the world similar to corn, pork bellies, orange juice etc.

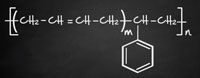

Synthetic latex is a man-made molecular copy of natural latex. The scientific name for this compound is Styrene-Butadiene (SBR).

Styrene is named for acirc;#128;#156;styraxacirc;#128;#157;, the resin from a Turkish tree. Low levels of styrene occur naturally in many kinds of plants as well as a variety of foods such as fruits, vegetables amp; nuts.

Butadiene is produced by dehydration of butane obtained from petroleum. Butadiene is also used in the manufacture of latex paints and nylon fibers used in rope and clothing.

Blended latex is just what it sounds like, a combination of Natural latex and Synthetic latex mixed together.

This

is a question thatacirc;#128;#153;s answer can depend on your perspective.

All latex formulas offer numerous benefits to consumers that far outweigh

the benefits of conventional foam bedding materials. Keep in mind that while

latex formulations are contrasted with each other below, all latex rubber

significantly outperforms foams such as memory foam or traditional polyurethane

foam for durability, pressure relief and sleep benefits.

This

is a question thatacirc;#128;#153;s answer can depend on your perspective.

All latex formulas offer numerous benefits to consumers that far outweigh

the benefits of conventional foam bedding materials. Keep in mind that while

latex formulations are contrasted with each other below, all latex rubber

significantly outperforms foams such as memory foam or traditional polyurethane

foam for durability, pressure relief and sleep benefits.

Natural latex, as its name implies, is acirc;#128;#156;naturalacirc;#128;#157; which offers many benefits for use in sleep products. Consumers that have an organic lifestyle and have made numerous changes to remove most synthetic chemicals from their household tend to purchase 100% natural formulations. The elasticity, healthiness, and ability of Natural Latex to conform to your body, reducing pressure on your muscles and circulation is unsurpassed. The resulting benefits and luxurious comfort simply canacirc;#128;#153;t be matched by synthetic latex. However, because it is a acirc;#128;#156;naturalacirc;#128;#157; product there are inconsistencies at the molecular level which cause Natural Latex products to wear at a faster rate than Synthetic Latex.

Synthetic Latex is extremely uniform at the molecular level, so sleep products will have greater durability than those made solely with Natural Latex. However, what you gain in durability you lose in feel and sleep benefits as compared to Natural Latex.

When consumers want to know a product is natural and good for the environment while also looking for a product that will help them sleep better with optimum value for their money- they purchase blended latex. By combining Natural Latex and Synthetic Latex together you get the best of both worlds. Natural components, elasticity, conformity, health benefits and luxurious feel from Natural Latex combine with extended durability from Synthetic Latex- to make a product that the Earth provided and we perfected.

Blended latex can be compared to a gold wedding band. No one has a 24 karat (100% gold) wedding band because it would be too soft and bend if gripped too hard. The solution is an 18 karat gold ring where the gold is mixed with another, more durable metal. The result is a ring that has the look and feel of pure gold but is less vulnerable to damage or wear.

907 Hollywood Way, Burbank 800-551-2010

12557 Harbor Blvd., Garden Grove 800-824-3145

1035 E. Camelback Rd.,

Phoenix AZ 800-477-0248

LatexpedicAcirc; Bedding

Material.

What

actually is

it?

Latex foam

mattresses are defined as: Any of several

natural or synthetic colloidal polymers suspended in an aqueous solution.

Basically: rubber particles in

water

WHAT IS

NATURAL LATEX

MATTRESSES?

Natural Latex is a milky substance harvested

from rubber tree plants (Havea brasiliensis) which are grown in tropical

climate plantations around the world. Most are located in Africa, Malaysia,

South America, and Indonesia. Natural Latex is bio-degradable and naturally

resistant to mold, mildew amp; bacteria.

Harvesting the liquid

latex foam

mattresses is similar to tapping trees

for maple syrup. The trees are not harmed, providing a sustainable resource.

The latex is collected in buckets and shipped to large rubber factories such

as B.F Goodrich, Dupont, etc. for processing. Natural liquid latex is a commodity

thatacirc;#128;#153;s publicly traded in stock markets around the world

similar to corn, pork bellies, orange juice etc.

WHAT IS SYNTHETIC

LATEX?

Synthetic latex is a man-made molecular

copy of natural latex. The scientific name for this compound is Styrene-Butadiene

(SBR).

Styrene is named for

acirc;#128;#156;styraxacirc;#128;#157;, the resin from a Turkish tree.

Low levels of styrene occur naturally in many kinds of plants as well as

a variety of foods such as fruits, vegetables amp; nuts.

Butadiene is produced by dehydration

of butane obtained from petroleum. Butadiene is also used in the manufacture

of latex paints and nylon fibers used in rope and clothing.

WHAT are

BLENDED LATEX foam

mattresses

?

Blended latex is just what it sounds

like, a combination of Natural latex and Synthetic latex mixed

together.

WHICH

LATEX

MATTRESS IS BEST FOR

ME?

This is a question

thatacirc;#128;#153;s answer can depend on your perspective. All latex

formulas offer numerous benefits to consumers that far outweigh the benefits

of conventional foam bedding materials. Keep in mind that while latex

formulations are contrasted with each other below, all latex rubber significantly

outperforms foams such as memory foam or traditional polyurethane foam for

durability, pressure relief and sleep benefits.

NATURAL LATEX

SYNTHETIC LATEX

Synthetic Latex is extremely uniform

at the molecular level, so sleep products will have greater durability than

those made solely with Natural Latex. However, what you gain in durability

you lose in feel and sleep benefits as compared to Natural Latex.

9" Latex

Mattress

11" Latex

Mattress

CLASSIC BLENDED

LATEX

When consumers want to know a product

is natural and good for the environment while also looking for a product

that will help them sleep better with optimum value for their money- they

purchase blended latex. By combining Natural Latex and Synthetic Latex together

you get the best of both worlds. Natural components, elasticity, conformity,

health benefits and luxurious feel from Natural Latex combine with extended

durability from Synthetic Latex- to make a product that the Earth provided

and we perfected.

Blended latex can be compared to a gold

wedding band. No one has a 24 karat (100% gold) wedding band because it would

be too soft and bend if gripped too hard. The solution is an 18 karat gold

ring where the gold is mixed with another, more durable metal. The result

is a ring that has the look and feel of pure gold but is less vulnerable

to damage or wear.

How Latex is Made

Making Latex acirc;#128;#147;

Manufacturing Processes

The terms

acirc;#128;#156;TALALAYacirc;#128;#157; and

acirc;#128;#156;Dunlopacirc;#128;#157; refer to the two different methods

of manufacturing Latex Rubber for sleep products. The Dunlop process was

developed in 1929. It was the first method used to produce latex material

for bedding.

As technology progressed, the TALALAY

process was developed by the TALALAY family during World War II. The TALALAY

process for producing latex is significantly more complex and costly, resulting

in softer, more buoyant and luxurious finished products.

MAKING LATEX - LATEX

FORMULAS

Both TALALAY and Dunlop processes start

with a formula mixture of liquid latex. These formulas can be any of the

following:

100% natural latex rubber (harvested

from rubber tree plants)

100% synthetic latex rubber (a man-made molecular

copy of natural latex rubber)

Blended natural amp; synthetic latex rubbers

(specific blend ratios are proprietary)

Note: there are small amounts of other

materials required for processing liquid latex into solid form which are

necessary for all latex production. (ingredients amp; amounts are

proprietary)

Latex International TALALAY is produced

using only 100% Natural or Blended formulations to meet optimum quality

standards.

Latex Processes

TALALAY

1. Liquid latex formulation is

poured into a mold and sealed closed

2. Vacuum is created to disperse liquid latex

throughout mold

3. Liquid latex is flash frozen

4. Frozen latex is flash heated to

acirc;#128;#156;gelacirc;#128;#157; into permanent solid

form

5. Cooled solid latex is removed from

mold

DUNLOP

1. Liquid latex formulation is

poured onto a long conveyor belt

2. Liquid latex is slowly heated to

acirc;#128;#156;gelacirc;#128;#157; into permanent solid

form

3. Cooled solid latex is removed from conveyor

belt

The difference in processing are the

two additional steps that occur with TALALAY Process - #2 vacuum amp; #3

freeze .

#2 Vacuum acirc;#128;#147;

This allows any amount of latex to be

evenly distributed throughout the mold creating precise and varied firmness

with the finished latex. The more liquid latex thatacirc;#128;#153;s poured

into the mold the firmer the resulting solid latex. Therefore, if less liquid

latex is used, a softer more supple piece of latex results.

This differs from Dunlop in that Dunlop

process has very little ability to vary the firmness or feel of the finished

solid product while maintaining its structural integrity. The liquid formula

is poured onto a belt and you get the same, dense piece of latex every time.

The only way to soften the feel of Dunlop latex is to add

acirc;#128;#156;fillersacirc;#128;#157; into the liquid latex formula

which result in solid latex that is flaky and breaks down quickly.

#3 Flash Freeze

acirc;#128;#147; This

provides TALALAY with its uniquely consistent characteristic.

Liquid latex is a suspension

of rubber particles in water, like

a shaken snow globe. Flash freezing prevents the latex particles from settling

to the bottom while gelling into a solid product. This means that the resulting

piece of solid TALALAY latex has the same consistent feel from top to bottom.

This differs from Dunlop because Dunlop

process does not utilize a freeze step. Therefore, the rubber particles settle

to the bottom while the liquid latex is gelling into a solid form, like a

snow globe, resulting in a variation of feel from top to bottom. This is

not recognizable if the Dunlop latex is used as a bottom layer of a mattress

but can cause problems if Dunlop pieces are used for pillows or as top layers

of a mattress.

CONCLUSION - The TALALAY process takes four times looonger than Dunlop with

two additional process steps that improve the consistency, quality and feel

of the finished latex.

A simple analogy: TALALAY latex is like

a chocolate soufflAtilde;copy;; although the process is long, your end

product is a buoyant, airy, complex delight. Dunlop latex is more like a

tray of brownies; tasty, but dense and flat in comparison.

Our commitment to perfection: From the

selection and mixing of raw materials to final product testing and assembly,

our entire manufacturing facility utilizes the latest technology to create

the most supple, resilient and comfortable TALALAY Latex sleep products in

the world.

But of course, all this technology

wonacirc;#128;#153;t get you anywhere without smart, talented professionals

to bring all the elements together assuring great finished products are delivered

to your home every time.

TALALAY latex is the premier material in

bedding, LI TALALAY delivers a unique

buoyant quality which relaxes muscles and relieves tension, lifting away

the pressures of the day while you sleep. Careful attention to detail at

every step makes certain this amazing feel comes through in the finished

product.

To help understand what makes our TALALAY

Latex so exceptional, think of an artisan chef creating a light and airy

chocolate soufflAtilde;copy;!

Use the best recipe

acirc;#128;#147;

Next, we mix our premium ingredients into a

liquid latex foam

formula or

acirc;#128;#156;batteracirc;#128;#157;. Creating different formulas

of liquid latex acirc;#128;#156;batteracirc;#128;#157;, we meet specific

customer requests for 100% natural or more commonly used blended

natural/synthetic latex recipes. Think dark chocolate vs, milk chocolate-

itacirc;#128;#153;s a matter of personal taste and desired product attributes.

Measure Carefully-

As any great baker knows, if

you donacirc;#128;#153;t measure correctly the soufflAtilde;copy; will

fail. Our advanced, state of the art automated systems control both the mix

of the batter and the precise amount poured into each mold to attain specific

results every time.

Test for Perfection -

Once the process is complete,

every mattress core is robotically tested in 9 areas to assure a consistent

feel from head to toe. Each pillow is individually weighed and hand inspected.

Share the Results -

Even the best ingredients and

the finest materials can be used poorly. To assure great finished products,

we follow through by sharing knowledge with our retail and manufacturing

partners. Together, we design and deliver finished pillows, mattress toppers

and mattresses that bring the uplifting benefits of TALALAY Latex to the

surface.

Please visit our product finder page to locate

products and companies in your area.

All of our TALALAY products are made

with Natural TALALAY Latex Rubber, which starts as sap from the Havea

brasiliensis tree. These rubber trees have a 25 year productive life and

a strong positive effect on the environment as they quickly absorb carbon

dioxide from the atmosphere and help reduce greenhouse

emissions.

Our TALALAY process features natural,

biodegradable ingredients that come from renewable resources and water-based

raw materials: natural latex, air, and water. Our process does not use solvents

and does not damage the ozone layer. Our clean and green approach carries

through to our end products: TALALAY latex contains no toxic chemicals while

standard Poly Foam and Memory Foam (visco) can contain as many as seven toxic

chemicals*

The Oeko-Tex Standard 100 (link

to oeko website) is the leading global testing and certification process

that ensures textile materials and home furnishing products do not contain

harmful substances or pose a health risk to consumers. Very few latex or

foam producers in the world meet the standards of this independent, third-party

certification. Click here to view our

OEKO-TEX Standard Certification.

All Latex International TALALAY Latex

products are certified OEKO-TEX Class 100; the healthiest classification.

This means that our products do not

contain allergenic materials that form carcinogenic arylamines of the MAK-groups

III A1 and III A2 (see the Oeko-Tex website for a list of chemicals included

in these groups,link to oeko), pesticides and chlorinated phenoles, heavy

metals or formaldehyde. Our TALALAY also meets the standard for skin friendly

pH and is free from chloro-organic carriers and biologically active finishes.

In other words,

Latex International TALALAY is the healthiest

material you can sleep on.

*Poly Foam and Visco Foam may contain

up to seven toxic chemicals: Tetrachoroethane, acetone, and dimethylformamide,

Methyl benzene, Methylene dianiline, toluene-neoprene and Vinilideine chloride,

one non-toxic chemical - diphenyl diisocyanate, and one natural material

(water.) Synthetic Latex has 5 non-toxic chemicals

(2-chloro-1acirc;#128;#147;3-butadiene, diphenyl diisocyanate, metallic

oxides, Phenol-melamine resins, sulfur, Tellerium) and 1 natural material

(water.) 100% Natural Latex has 6 non-toxic chemicals (acrylate resins, diphenyl

diisocyanate, Phenol-melamine resins, Phenol-urea, Polyvinyl acetate and

waxes styrene- butadiene copolymer) and 3 natural materials (fats, hevea

brasiliensis milk, and water.)

LI TALALAY Latex provides 33% more Pressure

Relief than leading Memory foam.

Pressure from your mattress and/or pillow

prevents your muscles from relaxing which makes it difficult to fall asleep

and impairs circulation causing you to toss amp; turn which makes it difficult

to stay asleep.

Therefore, the less pressure your mattress

and pillow produce on your body the easier it is to fall asleep and the more

complete sleep you achieve throughout the night which leads to more energetic

and productive days.

Garden Grove Store Serving Orange County with Latex Mattresses. 12557 Harbor Blvd., Garden Grove 800-824-3145

Latex International

TALALAY Latex is 4x more durable than other latex

and 20x more durable than traditional bedding

foams.

At Latex International, we continually

ensure that our formulas will last the test of time. Using the standardized

ASTM Cornell Indentation test we prove that our TALALAY outlasts any other

material used for bedding today.

This is the most rigorous and material

damaging ASTM standardized test that exists for bedding components. While

Latex International TALALAY performs flawlessly over a period of 12 hours

representing decades of use, other latexacirc;#128;#153;s break down much

more quickly and foams such as memory foam and polyurethane foam actually

tear apart within minutes.

The strength of our material allows

LI to match any warranty that retail stores choose to offer on their products

and assures maximum value for consumers.

Latex International TALALAY Latex breathes

up to 7x better than other latex or foams for cooler sleep.

One of the fastest growing concerns

with bedding today is sleeping hot. This is a legitimate concern because

not only is it uncomfortable, sleeping too hot interrupts the quality of

our sleep as we continuously move to find a cooler spot. This can occur from

both mattresses and pillows.

The heightened awareness of sleeping

hot is primarily due to increased use of Memory Foam in mattresses.

Memory Foam has a collapsible cell structure that

traps body heat and radiates it back at us resulting in uncomfortable

perspiration.

TALALAY Latex is sometimes confused

with Memory Foam because of extensive Memory Foam advertising. Nothing could

be farther from the truth. The TALALAY Latex rubber cell structure resists

collapsing and allows air to circulate. This breathability whisks away our

body heat preventing mattresses and pillows from becoming an oven.

Latex International has gone one step

further and developed TALALAY GL which is a unique formulation of TALALAY

Latex with special phase change properties. TALALAY GL actually helps regulate

the consistency of body temperature for a temperature neutral sleeping

experience.

Bedding Allergens

BEDDING

ALLERGENS

Mold, Mildew, Bacteria amp; Dust

Mites

LI TALALAY Latex is Mold, Mildew

amp; Bacteria proof and Dust Mite resistant

Most people donacirc;#128;#153;t

consider their mattress as a contributing source for respiratory problems

and allergic reactions. We think of our bed as a acirc;#128;#156;safe

havenacirc;#128;#157;. The reality can be much more yucky.

Mold, mildew, bacteria and dust mites

love our beds amp; pillows. We shed millions of microscopic skin cells and

perspire nearly 1 pint of water every night. The microscopic skin cells and

water vapor fall through the weave of our linens and mattress cover landing

on the cushioning layers below where they become a food and water source

for mold, mildew, bacteria and dust mites- it canacirc;#128;#153;t be

avoided, and it's gross.

Whether your acirc;#128;#156;landing

padacirc;#128;#157; cushion layer is hospitable to these infestations

is the controlling factor to the amount of hazardous dust created from your

mattress amp; pillow.

Foams such as Memory Foam amp;

Polyurethane Foam are environments

where these contaminants thrive, so if they compose the top cushion layers

of your mattress you may have a problem.

Independent testing shows that Latex

International TALALAY Latex is mold, mildew amp; bacteria proof- these organisms

simply wonacirc;#128;#153;t grow on it. Furthermore, itacirc;#128;#153;s

dust mite resistant so these critters will prefer to be elsewhere, not right

next to your face as you sleep.

Try to find a healthier bedding material,

we dare you.

In a perfect world all bedding products

would be as safe as Latex International's TALALAY Latex. The reality is that

todayacirc;#128;#153;s technology for producing foams like Memory Foam

or Polyurethane Foam simply aren't.

Todayacirc;#128;#153;s foams may

contain any or all of the following, each are known carcinogens.

Latex International TALALAY

Latex contains none of

these.

Zero cases of allergic reactions to

LI products have been reported.

Latex International Latex Mattresses have been

making TALALAY pillows and mattress components for over 35

years. Every year millions of products

are sold using Latex International TALALAY.

The FDA tracks allergic reactions to

latex products in the USA. Not once has there been a report of an allergic

reaction attributed to any of our TALALAY products.

Latex International is the only latex

producer that tests every block of mattress material in 9 separate areas

to insure consistency throughout each piece. This means that retailers and

consumers can be sure that products delivered or brought home will match

the products experienced in the showroom every single time.

Because pillows are not able to be measured

in the same way as block mattress material, we electronically weigh and then

hand inspect every pillow for quality and consistency. This is an extra time

consuming step in our process, but itacirc;#128;#153;s the only way to

be completely sure that consumers receive the very highest quality pillows

every single time.

Of the top four mattress companies in

the US, one spends more on annual advertising than the other three combined.

This company makes only Memory Foam beds. They spend tens of millions every

year advertising Memory Foam to consumers. To counter this, the remaining

top three US mattress companies (who make metal coil mattresses) also make

Memory Foam beds and advertise theirs to stay competitive.

Hence, the circle of abundant advertising

for Memory Foam.

Due to this advertising, many people

assume that all non-coil beds are made with Memory Foam or that Latex and

Memory Foam are the same thing. This couldnacirc;#128;#153;t be farther

from the truth.

In fact, the two materials are

actually polar opposites and the sleeping experience could not be more different!

Latex International TALALAY Latex actually outperforms

Memory Foam in every way.

Sleeping hot is the #1 complaint from

Memory Foam owners. This is because Memory Foam requires body heat to collapse

the Foam cell structure in order to conform to your curves, the collapsing

of these cells restricts air flow trapping body heat and radiating it back

at you.

Latex International TALALAY Latex

is 7x more breathable than memory foam. The rubber cell structure

doesnacirc;#128;#153;t collapse. Its natural resistance

lifts your body preventing collapse

and allows air to flow through, creating an escape path for body heat.

You wonacirc;#128;#153;t have to

continuously flip your Latex International TALALAY Latex pillow or search

for a cooler spot on your LI TALALAY Latex bed.

Our TALALAY Latex is a two-dimensional

material; itacirc;#128;#153;s simultaneously supportive and pressure

relieving, where memory foam is a one-dimensional- pressure reliever only.

Your body sinks into and through Memory

Foam until you hit a separate support layer below. Memory Foam simply

canacirc;#128;#153;t accomplish both pressure relief and support on its

own. Hitting the support layer below Memory Foam increases pressure on your

body.

Latex International TALALAY Latex is

different and testing proves it.

Our TALALAY Latex is the best pressure

relieving material used in bedding today. It provides the ultimate in pressure

relief so your muscles relax to fall asleep quickly and your circulation

can flow to stay asleep soundly.

Memory Foam, even so called

acirc;#128;#156;softacirc;#128;#157; memory foam has a hard dense feel

that is unappealing to many. Some call it acirc;#128;#156;getting stuck

in the mudacirc;#128;#157; because after a few minutes your body heat

collapses the cells and you sink into a hole molded to your body. It soon

becomes very difficult to move or get out of bed, you become trapped in a

temporary crater.

Latex International TALALAY Latex contains

naturally based rubber material that gently lifts your body for a light amp;

bouyant experience. Our TALALAY Latex instantly conforms and moves with your

body, providing postural support and exceptional muscle relief no matter

what sleeping position you maintain.

Latex International TALALAY Latex is

like floating- truly luxurious.

Our TALALAY Latex uses naturally derived

material harvested from rubber trees that create an inherently hypoallergenic,

dust-mite resistant, mold amp; mildew proof sleeping environment, making

it ideal for allergy sufferers or anyone wanting a cleaner bed. In addition

our TALALAY Latex doesnacirc;#128;#153;t off gas harmful compounds that

may be present in Memory Foam.

Cornell Indentation testing proves Latex

International TALALAY Latex is 20x more durable than leading Memory Foam.

While leading Memory Foam tears apart during this industry standard ASTM

quality test, our TALALAY Latex passes with flying

colors.

Latex International manufactures TALALAY

Latex Support Cores and Pressure relief layers used by top mattress manufacturers

around the world. The TALALAY process and our advanced technologies allow

us to create a wide range of firmnesses (ILDs) from ultra plush to extra

firm.

TALALAYClassic

(Talatech)

Our most popular and widely used

TALALAY Latex. Available in all standard mattress sizes.

Pressure Relief Layers: ILDacirc;#128;#153;s

14, 19, 24, 28, 32

Support Cores : ILDEcirc;#188;s 36, 40,

44

Unlike so called natural

acirc;#128;#156;soy based foamsacirc;#128;#157; that have a maximum

of 10% natural content, TALALAY 100% Natural utilizes 100% natural liquid

latex for a true eco-friendly solution.

Available in all standard mattress

sizes.

Pressure Relief Layers: N1, N2,

N3

Support Cores : N4,

N5

LI has the capability of making pillows

in 25 different sizes/profiles with 3 different firmness levels. All of which

can be made using any of our TALALAY formulations.

Toppers can be made using any TALALAY

formulation in any firmness (ILD) currently available

TECHNICAL BLOG

TalaWiki / TalaBlog / TalaTalk / TALALAY

Down the Truth / TalaTruth

FROM THE DESK OF DR. JOHN LEAN, PH.D.,

CHEMIST

Sometimes we find that we just have

to go to the doctor and get some straightforward information about the facts

and science behind latex.

Block latex foam rubber is the general

term used to describe latex foam rubber produced with a large enough cross

section to be used for mattresses, pillows, and cushions. Block latex foam

rubber is produced by two different processes: the TALALAY Process and the

Standard (Dunlop) Process. Both processes use the same basic ingredients:

natural rubber latex (NR), polystyrene-acirc;#128;#144;butadiene rubber

latex (SBR), soap, reinforcing filler, sulfur, and vulcanization

agents.

Natural Rubber

Latex acirc;#128;#147; Naturally occurring polyisoprene polymer

produced by rubber trees and extruded in the sap. The rubber tree sap is

collected, concentrated, and preserved with ammonia before being sold.

Polystyrene-butadiene Rubber

Latex acirc;#128;#147; Polymer

produced from styrene and butadiene designed to mimic and improve upon natural

rubber. The polymer is produced in water on both batch and continuous production

lines. After polymerization, the latex is stripped of residual reactants

and concentrated before being sold.

Soap acirc;#128;#147;

Natural soaps are used to stabilize

the various components in the mixture.

Reinforcing Filler

acirc;#128;#147; Hard materials

are added to the mixture to increase firmness.

Reinforcing fillers are of two

general types; mineral or plastic. Mineral fillers are generally aluminosilicates

such as Feldspar or calcium carbonate (talc). The most commonly used plastic

filler is polystyrene resin. Mineral fillers incorporate well into the

rubber matrix and tend to be

well dispersed. Plastic fillers are typically introduced as a latex and tend

to form clusters in the rubber matrix. The plastic clusters are prone to

breaking apart under use leading to

softening.

Sulfur acirc;#128;#147;

Elemental sulfur forms crosslinks between

polymer chains when heated giving the latex rubber foam strength and structure.

Vulcanization Agents acirc;#128;#147;

Agents used to increase the

crosslinking rate and effectiveness of sulfur. The agents are typically consumed

in the process. The above components are mixed together in a water based

system to form what is termed compound for both

processes.

STANDARD (DUNLOP)

PROCESS

Advantages of the TALALAY Process: the

resulting feel, the uniformity, and the ability to reach low densities of

the foam block as a result of the expansion of the foam to fill the mold

under reduced pressure (rather than the complete filling of the mold as in

the Standard (Dunlop) Process).Advantages of the Dunlop Process: shorter

production times and ease of manufacture.

TALALAY Comfort Zone

By: John Lean, Ph.D.

Director of Research and

Development

Latex International - Shelton,

Connecticut

REVIEWS NATURAL LATEX

MATTRESSES:

TALALAY Latex Mattresses of Rubber

Foam offer superior feel and comfort

in bedding materials because of its unique compression profile.

Compression is how

a material responds to a weight or load being placed on it. A material will

resist the load and push back in proportion to the load and the

materialacirc;#128;#153;s ability to carry the load. The manner in which

a material responds to a load defines how the material feels to the touch

and how it supports the load. Below is a graph showing the amount of force

needed to compress a piece of latex Rubber rubber and a coil spring a percentage

of the original height.

RATINGS LATEX

MATTRESSES: As shown in the

above graph, a coil spring has avery linear response to the applied load.

The linear response of a spring is an inherent property.

Talalay Latex Rubber Foam Mattress on the other hand

responds to the applied load in a non-linear

fashion. Initially TALALAY Latex Rubber

increases in firmness in response to the load, but as the load increases

TALALAY Latex Rubber compresses to a greater extent. TALALAY Latex Rubber

will support just as much weight at the coil spring, but it has more give

keeping the material from having the feeling of bottoming

out.

The increased compressibility

of TALALAY Latex Rubber Foam is what allows the material to shape itself

and comform to the human body. The

human bodyacirc;#128;#153;s profile is not flat and its weight distribution

is not even. A coil spring is only able to respond to a

bodyacirc;#128;#153;s weight and not its shape. TALALAY Latex Rubber with

its non-linear compression curve can respond to a bodyacirc;#128;#153;s

weight and shape. A person may have similar weight distribution between the

shoulders and hips, but the body parts have very different

shapes.

Our commitment to perfection: From the

selection and mixing of raw materials to final product testing and assembly,

our entire manufacturing facility utilizes the latest technology to create

the most supple, resilient and comfortable TALALAY Latex sleep products in

the world.

But of course, all this technology

wonacirc;#128;#153;t get you anywhere without smart, talented professionals

to bring all the elements together assuring great finished products are delivered

to your home every time.

TALALAY latex is the premier material in

bedding, LI TALALAY delivers a unique

buoyant quality which relaxes muscles and relieves tension, lifting away

the pressures of the day while you sleep. Careful attention to detail at

every step makes certain this amazing feel comes through in the finished

product.

To help understand what makes our TALALAY

Latex so exceptional, think of an artisan chef creating a light and airy

chocolate soufflAtilde;copy;!

Use the best recipe

acirc;#128;#147;

Next, we mix our premium ingredients into a

liquid latex foam

formula or

acirc;#128;#156;batteracirc;#128;#157;. Creating different formulas

of liquid latex acirc;#128;#156;batteracirc;#128;#157;, we meet specific

customer requests for 100% natural or more commonly used blended

natural/synthetic latex recipes. Think dark chocolate vs, milk chocolate-

itacirc;#128;#153;s a matter of personal taste and desired product attributes.

Measure Carefully-

As any great baker knows, if

you donacirc;#128;#153;t measure correctly the soufflAtilde;copy; will

fail. Our advanced, state of the art automated systems control both the mix

of the batter and the precise amount poured into each mold to attain specific

results every time.

Test for Perfection -

Once the process is complete,

every mattress core is robotically tested in 9 areas to assure a consistent

feel from head to toe. Each pillow is individually weighed and hand inspected.

Share the Results -

Even the best ingredients and

the finest materials can be used poorly. To assure great finished products,

we follow through by sharing knowledge with our retail and manufacturing

partners. Together, we design and deliver finished pillows, mattress toppers

and mattresses that bring the uplifting benefits of TALALAY Latex to the

surface.

Please visit our product finder page to locate

products and companies in your area.

All of our TALALAY products are made

with Natural TALALAY Latex Rubber, which starts as sap from the Havea

brasiliensis tree. These rubber trees have a 25 year productive life and

a strong positive effect on the environment as they quickly absorb carbon

dioxide from the atmosphere and help reduce greenhouse

emissions.

Our TALALAY process features natural,

biodegradable ingredients that come from renewable resources and water-based

raw materials: natural latex, air, and water. Our process does not use solvents

and does not damage the ozone layer. Our clean and green approach carries

through to our end products: TALALAY latex contains no toxic chemicals while

standard Poly Foam and Memory Foam (visco) can contain as many as seven toxic

chemicals*

The Oeko-Tex Standard 100 (link

to oeko website) is the leading global testing and certification process

that ensures textile materials and home furnishing products do not contain

harmful substances or pose a health risk to consumers. Very few latex or

foam producers in the world meet the standards of this independent, third-party

certification. Click here to view our

OEKO-TEX Standard Certification.

All Latex International TALALAY Latex

products are certified OEKO-TEX Class 100; the healthiest classification.

This means that our products do not

contain allergenic materials that form carcinogenic arylamines of the MAK-groups

III A1 and III A2 (see the Oeko-Tex website for a list of chemicals included

in these groups,link to oeko), pesticides and chlorinated phenoles, heavy

metals or formaldehyde. Our TALALAY also meets the standard for skin friendly

pH and is free from chloro-organic carriers and biologically active finishes.

In other words,

Latex International TALALAY is the healthiest

material you can sleep on.

*Poly Foam and Visco Foam may contain

up to seven toxic chemicals: Tetrachoroethane, acetone, and dimethylformamide,

Methyl benzene, Methylene dianiline, toluene-neoprene and Vinilideine chloride,

one non-toxic chemical - diphenyl diisocyanate, and one natural material

(water.) Synthetic Latex has 5 non-toxic chemicals

(2-chloro-1acirc;#128;#147;3-butadiene, diphenyl diisocyanate, metallic

oxides, Phenol-melamine resins, sulfur, Tellerium) and 1 natural material

(water.) 100% Natural Latex has 6 non-toxic chemicals (acrylate resins, diphenyl

diisocyanate, Phenol-melamine resins, Phenol-urea, Polyvinyl acetate and

waxes styrene- butadiene copolymer) and 3 natural materials (fats, hevea

brasiliensis milk, and water.)

LI TALALAY Latex provides 33% more Pressure

Relief than leading Memory foam.

Pressure from your mattress and/or pillow

prevents your muscles from relaxing which makes it difficult to fall asleep

and impairs circulation causing you to toss amp; turn which makes it difficult

to stay asleep.

Therefore, the less pressure your mattress

and pillow produce on your body the easier it is to fall asleep and the more

complete sleep you achieve throughout the night which leads to more energetic

and productive days.

Garden Grove Store Serving Orange County with Latex Mattresses. 12557 Harbor Blvd., Garden Grove 800-824-3145

Latex International

TALALAY Latex is 4x more durable than other latex

and 20x more durable than traditional bedding

foams.

At Latex International, we continually

ensure that our formulas will last the test of time. Using the standardized

ASTM Cornell Indentation test we prove that our TALALAY outlasts any other

material used for bedding today.

This is the most rigorous and material

damaging ASTM standardized test that exists for bedding components. While

Latex International TALALAY performs flawlessly over a period of 12 hours

representing decades of use, other latexacirc;#128;#153;s break down much

more quickly and foams such as memory foam and polyurethane foam actually

tear apart within minutes.

The strength of our material allows

LI to match any warranty that retail stores choose to offer on their products

and assures maximum value for consumers.

Latex International TALALAY Latex breathes

up to 7x better than other latex or foams for cooler sleep.

One of the fastest growing concerns

with bedding today is sleeping hot. This is a legitimate concern because

not only is it uncomfortable, sleeping too hot interrupts the quality of

our sleep as we continuously move to find a cooler spot. This can occur from

both mattresses and pillows.

The heightened awareness of sleeping

hot is primarily due to increased use of Memory Foam in mattresses.

Memory Foam has a collapsible cell structure that

traps body heat and radiates it back at us resulting in uncomfortable

perspiration.

TALALAY Latex is sometimes confused

with Memory Foam because of extensive Memory Foam advertising. Nothing could

be farther from the truth. The TALALAY Latex rubber cell structure resists

collapsing and allows air to circulate. This breathability whisks away our

body heat preventing mattresses and pillows from becoming an oven.

Latex International has gone one step

further and developed TALALAY GL which is a unique formulation of TALALAY

Latex with special phase change properties. TALALAY GL actually helps regulate

the consistency of body temperature for a temperature neutral sleeping

experience.

Bedding Allergens

BEDDING

ALLERGENS

Mold, Mildew, Bacteria amp; Dust

Mites

LI TALALAY Latex is Mold, Mildew

amp; Bacteria proof and Dust Mite resistant

Most people donacirc;#128;#153;t

consider their mattress as a contributing source for respiratory problems

and allergic reactions. We think of our bed as a acirc;#128;#156;safe

havenacirc;#128;#157;. The reality can be much more yucky.

Mold, mildew, bacteria and dust mites

love our beds amp; pillows. We shed millions of microscopic skin cells and

perspire nearly 1 pint of water every night. The microscopic skin cells and

water vapor fall through the weave of our linens and mattress cover landing

on the cushioning layers below where they become a food and water source

for mold, mildew, bacteria and dust mites- it canacirc;#128;#153;t be

avoided, and it's gross.

Whether your acirc;#128;#156;landing

padacirc;#128;#157; cushion layer is hospitable to these infestations

is the controlling factor to the amount of hazardous dust created from your

mattress amp; pillow.

Foams such as Memory Foam amp;

Polyurethane Foam are environments

where these contaminants thrive, so if they compose the top cushion layers

of your mattress you may have a problem.

Independent testing shows that Latex

International TALALAY Latex is mold, mildew amp; bacteria proof- these organisms

simply wonacirc;#128;#153;t grow on it. Furthermore, itacirc;#128;#153;s

dust mite resistant so these critters will prefer to be elsewhere, not right

next to your face as you sleep.

Try to find a healthier bedding material,

we dare you.

In a perfect world all bedding products

would be as safe as Latex International's TALALAY Latex. The reality is that

todayacirc;#128;#153;s technology for producing foams like Memory Foam

or Polyurethane Foam simply aren't.

Todayacirc;#128;#153;s foams may

contain any or all of the following, each are known carcinogens.

Latex International TALALAY

Latex contains none of

these.

Zero cases of allergic reactions to

LI products have been reported.

Latex International Latex Mattresses have been

making TALALAY pillows and mattress components for over 35

years. Every year millions of products

are sold using Latex International TALALAY.

The FDA tracks allergic reactions to

latex products in the USA. Not once has there been a report of an allergic

reaction attributed to any of our TALALAY products.

Latex International is the only latex

producer that tests every block of mattress material in 9 separate areas

to insure consistency throughout each piece. This means that retailers and

consumers can be sure that products delivered or brought home will match

the products experienced in the showroom every single time.

Because pillows are not able to be measured

in the same way as block mattress material, we electronically weigh and then

hand inspect every pillow for quality and consistency. This is an extra time

consuming step in our process, but itacirc;#128;#153;s the only way to

be completely sure that consumers receive the very highest quality pillows

every single time.

TALALAY Latex vs Memory

Foam

Of the top four mattress companies in

the US, one spends more on annual advertising than the other three combined.

This company makes only Memory Foam beds. They spend tens of millions every

year advertising Memory Foam to consumers. To counter this, the remaining

top three US mattress companies (who make metal coil mattresses) also make

Memory Foam beds and advertise theirs to stay competitive.

Hence, the circle of abundant advertising

for Memory Foam.

Due to this advertising, many people

assume that all non-coil beds are made with Memory Foam or that Latex and

Memory Foam are the same thing. This couldnacirc;#128;#153;t be farther

from the truth.

In fact, the two materials are

actually polar opposites and the sleeping experience could not be more different!

Latex International TALALAY Latex actually outperforms

Memory Foam in every way.

Sleeping hot is the #1 complaint from

Memory Foam owners. This is because Memory Foam requires body heat to collapse

the Foam cell structure in order to conform to your curves, the collapsing

of these cells restricts air flow trapping body heat and radiating it back

at you.

Latex International TALALAY Latex

is 7x more breathable than memory foam. The rubber cell structure

doesnacirc;#128;#153;t collapse. Its natural resistance

lifts your body preventing collapse

and allows air to flow through, creating an escape path for body heat.

You wonacirc;#128;#153;t have to

continuously flip your Latex International TALALAY Latex pillow or search

for a cooler spot on your LI TALALAY Latex bed.

Our TALALAY Latex is a two-dimensional

material; itacirc;#128;#153;s simultaneously supportive and pressure

relieving, where memory foam is a one-dimensional- pressure reliever only.

Your body sinks into and through Memory

Foam until you hit a separate support layer below. Memory Foam simply

canacirc;#128;#153;t accomplish both pressure relief and support on its

own. Hitting the support layer below Memory Foam increases pressure on your

body.

Latex International TALALAY Latex is

different and testing proves it.

Our TALALAY Latex is the best pressure

relieving material used in bedding today. It provides the ultimate in pressure

relief so your muscles relax to fall asleep quickly and your circulation

can flow to stay asleep soundly.

Memory Foam, even so called

acirc;#128;#156;softacirc;#128;#157; memory foam has a hard dense feel

that is unappealing to many. Some call it acirc;#128;#156;getting stuck

in the mudacirc;#128;#157; because after a few minutes your body heat

collapses the cells and you sink into a hole molded to your body. It soon

becomes very difficult to move or get out of bed, you become trapped in a

temporary crater.

Latex International TALALAY Latex contains

naturally based rubber material that gently lifts your body for a light amp;

bouyant experience. Our TALALAY Latex instantly conforms and moves with your

body, providing postural support and exceptional muscle relief no matter

what sleeping position you maintain.

Latex International TALALAY Latex is

like floating- truly luxurious.

Our TALALAY Latex uses naturally derived

material harvested from rubber trees that create an inherently hypoallergenic,

dust-mite resistant, mold amp; mildew proof sleeping environment, making

it ideal for allergy sufferers or anyone wanting a cleaner bed. In addition

our TALALAY Latex doesnacirc;#128;#153;t off gas harmful compounds that

may be present in Memory Foam.

Cornell Indentation testing proves Latex

International TALALAY Latex is 20x more durable than leading Memory Foam.

While leading Memory Foam tears apart during this industry standard ASTM

quality test, our TALALAY Latex passes with flying

colors.

Latex International manufactures TALALAY

Latex Support Cores and Pressure relief layers used by top mattress manufacturers

around the world. The TALALAY process and our advanced technologies allow

us to create a wide range of firmnesses (ILDs) from ultra plush to extra

firm.

TALALAYClassic

(Talatech)

Our most popular and widely used

TALALAY Latex. Available in all standard mattress sizes.

Pressure Relief Layers: ILDacirc;#128;#153;s

14, 19, 24, 28, 32

Support Cores : ILDEcirc;#188;s 36, 40,

44

Unlike so called natural

acirc;#128;#156;soy based foamsacirc;#128;#157; that have a maximum

of 10% natural content, TALALAY 100% Natural utilizes 100% natural liquid

latex for a true eco-friendly solution.

Available in all standard mattress

sizes.

Pressure Relief Layers: N1, N2,

N3

Support Cores : N4,

N5

LI has the capability of making pillows

in 25 different sizes/profiles with 3 different firmness levels. All of which

can be made using any of our TALALAY formulations.

Toppers can be made using any TALALAY

formulation in any firmness (ILD) currently available

TECHNICAL BLOG

TalaWiki / TalaBlog / TalaTalk / TALALAY

Down the Truth / TalaTruth

FROM THE DESK OF DR. JOHN LEAN, PH.D.,

CHEMIST

Sometimes we find that we just have

to go to the doctor and get some straightforward information about the facts

and science behind latex.

Block latex foam rubber is the general

term used to describe latex foam rubber produced with a large enough cross

section to be used for mattresses, pillows, and cushions. Block latex foam

rubber is produced by two different processes: the TALALAY Process and the

Standard (Dunlop) Process. Both processes use the same basic ingredients:

natural rubber latex (NR), polystyrene-acirc;#128;#144;butadiene rubber

latex (SBR), soap, reinforcing filler, sulfur, and vulcanization

agents.

Natural Rubber

Latex acirc;#128;#147; Naturally occurring polyisoprene polymer

produced by rubber trees and extruded in the sap. The rubber tree sap is

collected, concentrated, and preserved with ammonia before being sold.

Polystyrene-butadiene Rubber

Latex acirc;#128;#147; Polymer

produced from styrene and butadiene designed to mimic and improve upon natural

rubber. The polymer is produced in water on both batch and continuous production

lines. After polymerization, the latex is stripped of residual reactants

and concentrated before being sold.

Soap acirc;#128;#147;

Natural soaps are used to stabilize

the various components in the mixture.

Reinforcing Filler

acirc;#128;#147; Hard materials

are added to the mixture to increase firmness.

Reinforcing fillers are of two

general types; mineral or plastic. Mineral fillers are generally aluminosilicates

such as Feldspar or calcium carbonate (talc). The most commonly used plastic

filler is polystyrene resin. Mineral fillers incorporate well into the

rubber matrix and tend to be

well dispersed. Plastic fillers are typically introduced as a latex and tend

to form clusters in the rubber matrix. The plastic clusters are prone to

breaking apart under use leading to

softening.

Sulfur acirc;#128;#147;

Elemental sulfur forms crosslinks between

polymer chains when heated giving the latex rubber foam strength and structure.

Vulcanization Agents acirc;#128;#147;

Agents used to increase the

crosslinking rate and effectiveness of sulfur. The agents are typically consumed

in the process. The above components are mixed together in a water based

system to form what is termed compound for both

processes.

STANDARD (DUNLOP)

PROCESS

Advantages of the TALALAY Process: the

resulting feel, the uniformity, and the ability to reach low densities of

the foam block as a result of the expansion of the foam to fill the mold

under reduced pressure (rather than the complete filling of the mold as in

the Standard (Dunlop) Process).Advantages of the Dunlop Process: shorter

production times and ease of manufacture.

TALALAY Comfort Zone

By: John Lean, Ph.D.

Director of Research and

Development

Latex International - Shelton,

Connecticut

REVIEWS NATURAL LATEX

MATTRESSES:

TALALAY Latex Mattresses of Rubber

Foam offer superior feel and comfort

in bedding materials because of its unique compression profile.

Compression is how

a material responds to a weight or load being placed on it. A material will

resist the load and push back in proportion to the load and the

materialacirc;#128;#153;s ability to carry the load. The manner in which

a material responds to a load defines how the material feels to the touch

and how it supports the load. Below is a graph showing the amount of force

needed to compress a piece of latex Rubber rubber and a coil spring a percentage

of the original height.

RATINGS LATEX

MATTRESSES: As shown in the

above graph, a coil spring has avery linear response to the applied load.

The linear response of a spring is an inherent property.

Talalay Latex Rubber Foam Mattress on the other hand

responds to the applied load in a non-linear

fashion. Initially TALALAY Latex Rubber

increases in firmness in response to the load, but as the load increases

TALALAY Latex Rubber compresses to a greater extent. TALALAY Latex Rubber

will support just as much weight at the coil spring, but it has more give

keeping the material from having the feeling of bottoming

out.

The increased compressibility

of TALALAY Latex Rubber Foam is what allows the material to shape itself

and comform to the human body. The

human bodyacirc;#128;#153;s profile is not flat and its weight distribution

is not even. A coil spring is only able to respond to a

bodyacirc;#128;#153;s weight and not its shape. TALALAY Latex Rubber with

its non-linear compression curve can respond to a bodyacirc;#128;#153;s

weight and shape. A person may have similar weight distribution between the

shoulders and hips, but the body parts have very different

shapes.

Our commitment to perfection: From the

selection and mixing of raw materials to final product testing and assembly,

our entire manufacturing facility utilizes the latest technology to create

the most supple, resilient and comfortable TALALAY Latex sleep products in

the world.

But of course, all this technology

wonacirc;#128;#153;t get you anywhere without smart, talented professionals

to bring all the elements together assuring great finished products are delivered

to your home every time.

TALALAY latex is the premier material in

bedding, LI TALALAY delivers a unique

buoyant quality which relaxes muscles and relieves tension, lifting away

the pressures of the day while you sleep. Careful attention to detail at

every step makes certain this amazing feel comes through in the finished

product.

To help understand what makes our TALALAY

Latex so exceptional, think of an artisan chef creating a light and airy

chocolate soufflAtilde;copy;!

Use the best recipe

acirc;#128;#147;

Next, we mix our premium ingredients into a

liquid latex foam

formula or

acirc;#128;#156;batteracirc;#128;#157;. Creating different formulas

of liquid latex acirc;#128;#156;batteracirc;#128;#157;, we meet specific

customer requests for 100% natural or more commonly used blended

natural/synthetic latex recipes. Think dark chocolate vs, milk chocolate-

itacirc;#128;#153;s a matter of personal taste and desired product attributes.

Measure Carefully-

As any great baker knows, if

you donacirc;#128;#153;t measure correctly the soufflAtilde;copy; will

fail. Our advanced, state of the art automated systems control both the mix

of the batter and the precise amount poured into each mold to attain specific

results every time.

Test for Perfection -

Once the process is complete,

every mattress core is robotically tested in 9 areas to assure a consistent

feel from head to toe. Each pillow is individually weighed and hand inspected.

Share the Results -

Even the best ingredients and

the finest materials can be used poorly. To assure great finished products,

we follow through by sharing knowledge with our retail and manufacturing

partners. Together, we design and deliver finished pillows, mattress toppers

and mattresses that bring the uplifting benefits of TALALAY Latex to the

surface.

Please visit our product finder page to locate

products and companies in your area.

All of our TALALAY products are made

with Natural TALALAY Latex Rubber, which starts as sap from the Havea

brasiliensis tree. These rubber trees have a 25 year productive life and

a strong positive effect on the environment as they quickly absorb carbon

dioxide from the atmosphere and help reduce greenhouse

emissions.

Our TALALAY process features natural,

biodegradable ingredients that come from renewable resources and water-based

raw materials: natural latex, air, and water. Our process does not use solvents

and does not damage the ozone layer. Our clean and green approach carries

through to our end products: TALALAY latex contains no toxic chemicals while

standard Poly Foam and Memory Foam (visco) can contain as many as seven toxic

chemicals*

The Oeko-Tex Standard 100 (link

to oeko website) is the leading global testing and certification process

that ensures textile materials and home furnishing products do not contain

harmful substances or pose a health risk to consumers. Very few latex or

foam producers in the world meet the standards of this independent, third-party

certification.

Click here

to view our OEKO-TEX Standard Certification.

All Latex International TALALAY Latex

products are certified OEKO-TEX Class 100; the healthiest classification.

This means that our products do not

contain allergenic materials that form carcinogenic arylamines of the MAK-groups

III A1 and III A2 (see the Oeko-Tex website for a list of chemicals included

in these groups,link to oeko), pesticides and chlorinated phenoles, heavy

metals or formaldehyde. Our TALALAY also meets the standard for skin friendly

pH and is free from chloro-organic carriers and biologically active finishes.

In other words,

Latex International TALALAY is the healthiest

material you can sleep on.

*Poly Foam and Visco Foam may contain

up to seven toxic chemicals: Tetrachoroethane, acetone, and dimethylformamide,

Methyl benzene, Methylene dianiline, toluene-neoprene and Vinilideine chloride,

one non-toxic chemical - diphenyl diisocyanate, and one natural material

(water.) Synthetic Latex has 5 non-toxic chemicals

(2-chloro-1acirc;#128;#147;3-butadiene, diphenyl diisocyanate, metallic

oxides, Phenol-melamine resins, sulfur, Tellerium) and 1 natural material

(water.) 100% Natural Latex has 6 non-toxic chemicals (acrylate resins, diphenyl

diisocyanate, Phenol-melamine resins, Phenol-urea, Polyvinyl acetate and

waxes styrene- butadiene copolymer) and 3 natural materials (fats, hevea

brasiliensis milk, and water.)

LI TALALAY Latex provides 33% more Pressure

Relief than leading Memory foam.

Pressure from your mattress and/or pillow

prevents your muscles from relaxing which makes it difficult to fall asleep

and impairs circulation causing you to toss amp; turn which makes it difficult

to stay asleep.

Therefore, the less pressure your mattress

and pillow produce on your body the easier it is to fall asleep and the more

complete sleep you achieve throughout the night which leads to more energetic

and productive days.

Garden Grove Store Serving Orange County with Latex Mattresses. 12557 Harbor Blvd., Garden Grove 800-824-3145

Latex International

TALALAY Latex is 4x more durable than other latex

and 20x more durable than traditional bedding

foams.

At Latex International, we continually

ensure that our formulas will last the test of time. Using the standardized

ASTM Cornell Indentation test we prove that our TALALAY outlasts any other

material used for bedding today.

This is the most rigorous and material

damaging ASTM standardized test that exists for bedding components. While

Latex International TALALAY performs flawlessly over a period of 12 hours

representing decades of use, other latexacirc;#128;#153;s break down much

more quickly and foams such as memory foam and polyurethane foam actually

tear apart within minutes.

The strength of our material allows

LI to match any warranty that retail stores choose to offer on their products

and assures maximum value for consumers.

Latex International TALALAY Latex breathes

up to 7x better than other latex or foams for cooler sleep.

One of the fastest growing concerns

with bedding today is sleeping hot. This is a legitimate concern because

not only is it uncomfortable, sleeping too hot interrupts the quality of

our sleep as we continuously move to find a cooler spot. This can occur from

both mattresses and pillows.

The heightened awareness of sleeping

hot is primarily due to increased use of Memory Foam in mattresses.

Memory Foam has a collapsible cell structure that

traps body heat and radiates it back at us resulting in uncomfortable

perspiration.

TALALAY Latex is sometimes confused

with Memory Foam because of extensive Memory Foam advertising. Nothing could

be farther from the truth. The TALALAY Latex rubber cell structure resists

collapsing and allows air to circulate. This breathability whisks away our

body heat preventing mattresses and pillows from becoming an oven.

Latex International has gone one step

further and developed TALALAY GL which is a unique formulation of TALALAY

Latex with special phase change properties. TALALAY GL actually helps regulate

the consistency of body temperature for a temperature neutral sleeping

experience.

Bedding Allergens

BEDDING

ALLERGENS

Mold, Mildew, Bacteria amp; Dust

Mites

LI TALALAY Latex is Mold, Mildew

amp; Bacteria proof and Dust Mite resistant

Most people donacirc;#128;#153;t

consider their mattress as a contributing source for respiratory problems

and allergic reactions. We think of our bed as a acirc;#128;#156;safe

havenacirc;#128;#157;. The reality can be much more yucky.

Mold, mildew, bacteria and dust mites

love our beds amp; pillows. We shed millions of microscopic skin cells and

perspire nearly 1 pint of water every night. The microscopic skin cells and

water vapor fall through the weave of our linens and mattress cover landing

on the cushioning layers below where they become a food and water source

for mold, mildew, bacteria and dust mites- it canacirc;#128;#153;t be

avoided, and it's gross.

Whether your acirc;#128;#156;landing

padacirc;#128;#157; cushion layer is hospitable to these infestations

is the controlling factor to the amount of hazardous dust created from your

mattress amp; pillow.

Foams such as Memory Foam amp;

Polyurethane Foam are environments

where these contaminants thrive, so if they compose the top cushion layers

of your mattress you may have a problem.

Independent testing shows that Latex

International TALALAY Latex is mold, mildew amp; bacteria proof- these organisms

simply wonacirc;#128;#153;t grow on it. Furthermore, itacirc;#128;#153;s

dust mite resistant so these critters will prefer to be elsewhere, not right

next to your face as you sleep.

Try to find a healthier bedding material,

we dare you.

In a perfect world all bedding products

would be as safe as Latex International's TALALAY Latex. The reality is that

todayacirc;#128;#153;s technology for producing foams like Memory Foam

or Polyurethane Foam simply aren't.

Todayacirc;#128;#153;s foams may

contain any or all of the following, each are known carcinogens.

Latex International TALALAY

Latex contains none of

these.

Zero cases of allergic reactions to

LI products have been reported.

Latex International Latex Mattresses have been

making TALALAY pillows and mattress components for over 35

years. Every year millions of products

are sold using Latex International TALALAY.

The FDA tracks allergic reactions to

latex products in the USA. Not once has there been a report of an allergic

reaction attributed to any of our TALALAY products.

Latex International is the only latex

producer that tests every block of mattress material in 9 separate areas

to insure consistency throughout each piece. This means that retailers and

consumers can be sure that products delivered or brought home will match

the products experienced in the showroom every single time.

Because pillows are not able to be measured

in the same way as block mattress material, we electronically weigh and then

hand inspect every pillow for quality and consistency. This is an extra time

consuming step in our process, but itacirc;#128;#153;s the only way to

be completely sure that consumers receive the very highest quality pillows

every single time.

Of the top four mattress companies in

the US, one spends more on annual advertising than the other three combined.

This company makes only Memory Foam beds. They spend tens of millions every

year advertising Memory Foam to consumers. To counter this, the remaining

top three US mattress companies (who make metal coil mattresses) also make

Memory Foam beds and advertise theirs to stay competitive.

Hence, the circle of abundant advertising

for Memory Foam.

Due to this advertising, many people

assume that all non-coil beds are made with Memory Foam or that Latex and

Memory Foam are the same thing. This couldnacirc;#128;#153;t be farther

from the truth.

In fact, the two materials are

actually polar opposites and the sleeping experience could not be more different!

Latex International TALALAY Latex actually outperforms

Memory Foam in every way.

Sleeping hot is the #1 complaint from

Memory Foam owners. This is because Memory Foam requires body heat to collapse

the Foam cell structure in order to conform to your curves, the collapsing

of these cells restricts air flow trapping body heat and radiating it back

at you.

Latex International TALALAY Latex

is 7x more breathable than memory foam. The rubber cell structure

doesnacirc;#128;#153;t collapse. Its natural resistance

lifts your body preventing collapse

and allows air to flow through, creating an escape path for body heat.

You wonacirc;#128;#153;t have to

continuously flip your Latex International TALALAY Latex pillow or search

for a cooler spot on your LI TALALAY Latex bed.

Our TALALAY Latex is a two-dimensional

material; itacirc;#128;#153;s simultaneously supportive and pressure

relieving, where memory foam is a one-dimensional- pressure reliever only.

Your body sinks into and through Memory

Foam until you hit a separate support layer below. Memory Foam simply

canacirc;#128;#153;t accomplish both pressure relief and support on its

own. Hitting the support layer below Memory Foam increases pressure on your

body.

Latex International TALALAY Latex is

different and testing proves it.

Our TALALAY Latex is the best pressure

relieving material used in bedding today. It provides the ultimate in pressure

relief so your muscles relax to fall asleep quickly and your circulation

can flow to stay asleep soundly.

Memory Foam, even so called

acirc;#128;#156;softacirc;#128;#157; memory foam has a hard dense feel

that is unappealing to many. Some call it acirc;#128;#156;getting stuck

in the mudacirc;#128;#157; because after a few minutes your body heat

collapses the cells and you sink into a hole molded to your body. It soon

becomes very difficult to move or get out of bed, you become trapped in a

temporary crater.

Latex International TALALAY Latex contains

naturally based rubber material that gently lifts your body for a light amp;

bouyant experience. Our TALALAY Latex instantly conforms and moves with your

body, providing postural support and exceptional muscle relief no matter

what sleeping position you maintain.

Latex International TALALAY Latex is

like floating- truly luxurious.

Our TALALAY Latex uses naturally derived

material harvested from rubber trees that create an inherently hypoallergenic,

dust-mite resistant, mold amp; mildew proof sleeping environment, making

it ideal for allergy sufferers or anyone wanting a cleaner bed. In addition

our TALALAY Latex doesnacirc;#128;#153;t off gas harmful compounds that

may be present in Memory Foam.

Cornell Indentation testing proves Latex

International TALALAY Latex is 20x more durable than leading Memory Foam.

While leading Memory Foam tears apart during this industry standard ASTM

quality test, our TALALAY Latex passes with flying

colors.

Latex International manufactures TALALAY

Latex Support Cores and Pressure relief layers used by top mattress manufacturers

around the world. The TALALAY process and our advanced technologies allow

us to create a wide range of firmnesses (ILDs) from ultra plush to extra

firm.

TALALAYClassic

(Talatech)

Our most popular and widely used

TALALAY Latex. Available in all standard mattress sizes.

Pressure Relief Layers: ILDacirc;#128;#153;s

14, 19, 24, 28, 32

Support Cores : ILDEcirc;#188;s 36, 40,

44

Unlike so called natural

acirc;#128;#156;soy based foamsacirc;#128;#157; that have a maximum

of 10% natural content, TALALAY 100% Natural utilizes 100% natural liquid

latex for a true eco-friendly solution.

Available in all standard mattress

sizes.

Pressure Relief Layers: N1, N2,

N3

Support Cores : N4,

N5

LI has the capability of making pillows

in 25 different sizes/profiles with 3 different firmness levels. All of which

can be made using any of our TALALAY formulations.

Toppers can be made using any TALALAY

formulation in any firmness (ILD) currently available

TECHNICAL BLOG

TalaWiki / TalaBlog / TalaTalk / TALALAY

Down the Truth / TalaTruth

FROM THE DESK OF DR. JOHN LEAN, PH.D.,

CHEMIST

Sometimes we find that we just have

to go to the doctor and get some straightforward information about the facts

and science behind latex.

Block latex foam rubber is the general

term used to describe latex foam rubber produced with a large enough cross